The metal core of the thermal PCB can be aluminium (aluminium core PCB), copper (copper core PCB or a heavy copper PCB) or a mixture of special alloys. The most common is an aluminium core PCB. Other materials, like brass or steel, are sometimes requested but are not recommended. The metal PCB materials are very hard and cutting the PCB into smaller pieces can pose problems. Other considerations in selecting metal PCB materials are the chemicals in manufacturing and if the metal will react to them.

The thickness of metal cores in PCB base plates is typically 30 mil - 125 mil, but thicker and thinner plates are possible.

MCPCB copper foil thickness can be 1 - 10 oz. MCPCBs can be advantageous to use for their ability to integrate a dielectric polymer layer with a high thermal conductivity for a lower thermal resistance. Metal core PCBs transfer heat 8 to 9 times faster than FR4 PCBs. MCPCB laminates dissipate heat, keeping heat generating components cooler which results in increased performance and life.

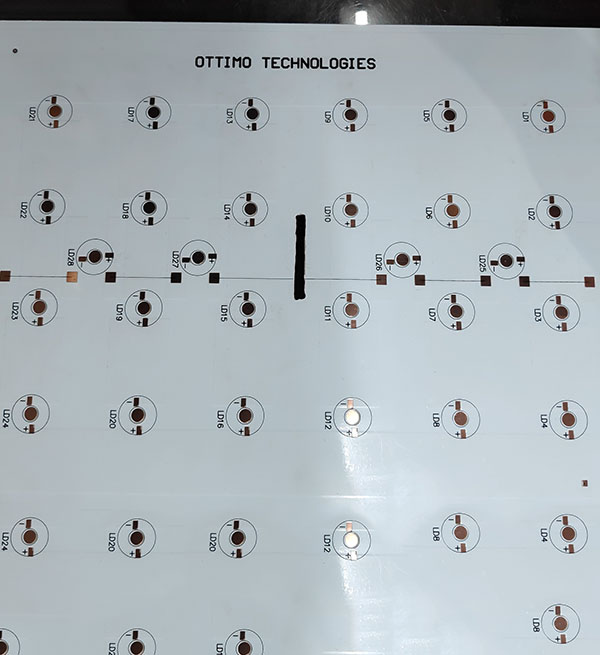

COPPER TRACE PCB is dedicated to provide finest quality Metal Core PCBs, to our customer’s requirement.